The mobile pellet plant through our R&D is manufactured for professional pelletization. Main equipments within it include pulverizer, cyclone separator, silo, feeder, pellet mill, vibrating screen, bag type dust collector, foundation frame and electric cabinet. It can not only pelletize sawdust, stalks and straw, but also process forage and fodder for animals.

The raw materials of this small mobile pellet plant are mainly wastes or residues from furniture factory, wood processing factory or sawmill, such as logs, waste wood chips, waste pieces, tree branches, sawdust, wood shaving, feedstock, cover sawdust, twigs, straw, rice husks, peanut shells and so on.

The range of diameter of pellets: 6-12mm, with pellet density of 1.1-1.3t/m3 and moisture content of ≤8%;

Overall size (L*W*H): 3720X2080X2080;

Total installed capacity: 40.65KW

Specifications:

|

Model

|

Capacity | Pellet diameter | Power | size |

| MPL300 | 250-350kg/h | 6-12mm | 41.25kw | 3500*1960*3500mm |

| MPL400 | 350-450kg/h | 6-12mm | 49.25kw | 3500*1960*3500mm |

Process flow

Pulverizer-----Cyclone Separator-----Surge Bin----Screw Elevator----Feeder----PMZL-300B Pellet Mill-----Vibrating Screen-----Finished Products-----Bag Type Dust Collector

1. Pulverizer

The complete plant adopts hammer mill herewith, for the pulverizing section, the output of which is due chiefly to the size and moisture content of the feedstock and mesh size.

2. Surge bin

The bin is for feedstock storage. Here are two ways of putting the feedstock into the bin. On the one hand, thanks to air flow, the pulverized material will fall into the bin via cyclone separator; on the other hand, feedstock in qualified size can be added in straightforward from the bin inlet.

3. Screw elevator

The screw elevator, also known as screw conveyer hereby, is used to convey materials driven directly by the motor.

4. Feeder

The feeder, more like shape and structure of the screw conveyer aforementioned, is for putting feed into the pellet mill continuously.

4.1 The TRBs on each end shall be lubricated every four working hours.

4.2 Check oil level of the reduction gearbox on the feeder monthly, with the oil taking up one third of the gearbox. If not, please add it.

5. PMZL-300B pellet mill

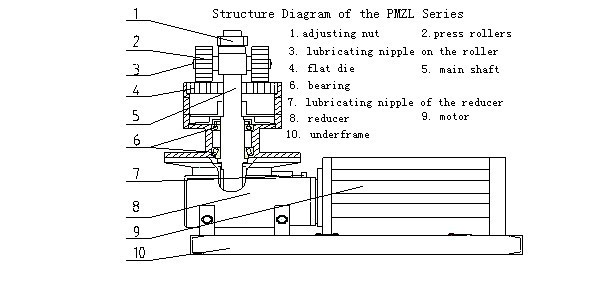

1. adjusting nut 2.press rollers 3. lubricating nipple on the roller 4. flat die 5. main shaft 6 bearing 7.lubricating nipple of the reducer 8. reducer 9. motor 10. underframe

Scope of application

The PMZL series of pellet mills are professionally designed to process biomass raw materials via technological innovation. The sphere of raw materials covers sawdust, straw, rice husks, bamboo shavings, peanut shells, bagasse, alfalfa and so forth.

Performance features

1) Thanks to the case-hardening and carburizing treatment as well as grinding and fine processing, the gear within the pellet mill gearbox made of superior alloy steel features stable transmission, low noise, high bearing capacity, steady temperature and a long life.

2) The main shaft is equipped with TRBs for enduring heavy axial forces and prolonging service life.

3) The application of longer diameter press rollers can help to achieve higher yield characterized with better pelletizing rate as well as even pellet quality and hardness.

4) Both rollers and the die have been processed under anti-resistant treatment. Specifically, the flat die can be efficiently used double face for a longer life span.

5) Applying seal structure to all bearings can efficaciously prevent dust and ash from falling in and extend life of bearings.

6) The optional pellet diameters range is 6mm -12mm.

6. Vibrating screen

As a sifter, the vibrating screen also can help to cool pellets down at the same time. The pellet crumb and scraps collected under the wire mesh shall be cleaned away timely. Simultaneously, qualified pellets will be discharged at the rear outlet. During the operation, the sifter works stably.

What's more, vibrating frequency can be converted. However, the rotating directions of the two motors shall keep opposite.

7. Bag type dust collector

It's mainly for collecting powdery materials and dusts. Thanks to the collector equipped with an induced fan, the ash content of the exhausted air will remarkably reduced on one hand, and on the other, not only can pellets be cooled in the meantime, but the working environment can be kept as much clean as possible.

The fan possessing power of 3 KW and air volume of 2664-5268m3/h can suck powdery crumb and dust into the collector and filter them which will then be exhausted out to the open air. The whole set of bags can vibrate automatically and the shaking time and interval can be preset by simply adjusting the time relay. But crumb and dust will be piled up on the drawer of the collector. Please dump them timely or put them back to use into the surge bin.

You are welcome to contact us for more details of this small mobile pellet plant.