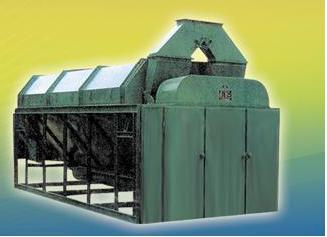

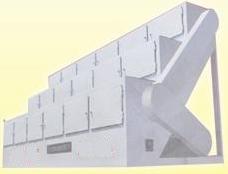

Drum Hull Beater

Those Drum Hull Beater is an improved model

separator, after having undergone our modifications. Its design features are based on the traditional product but include a number of enhancements, implemented after in-depth research on cottonseed oil plants and on the characteristics of cottonseed while processing.

Screening effect: kernel ratio in hull is 0.5% max;

Hulls ratio in kernel is 16% max

It's easy to install & operate without making any adjustments.

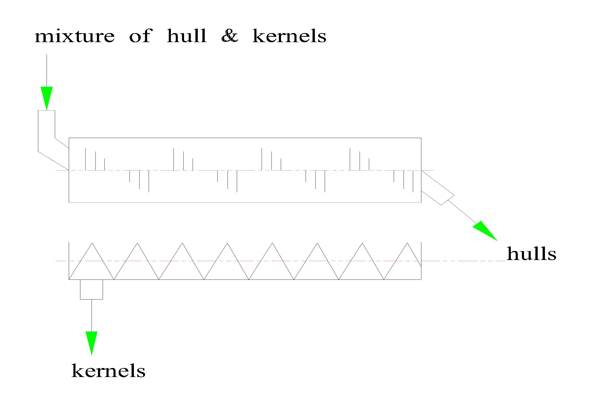

Working Principle

To separat the hull & kernels according to the different gravity of hull & kernels.

Classification of drum beater hulls

Single drum beater huller

Layer hull beater

Step hull beater

Different Models Hull Beater

Single Huller Beater

|

Model

|

Capacity(T/D)

|

Power(KW)

|

Weight(kg)

|

Dimension(mm) |

|

GCLY50

|

25-30

|

3

|

850

|

3650*900*1400

|

Double Huller Beater

|

Model |

GCLY2-50 |

GCLY2-80 |

|

Capacity(T/D) |

50-60 |

80-100 |

|

Power(KW) |

4 |

7.5 |

|

Weight(kg) |

1350 |

2860 |

|

Dimension(mm) |

3450*1450*1950 |

4800*2000*2600 |

Layer Huller Beater

|

Model |

GCLY3-80 |

GCLY3-100 |

|

Capacity(T/D) |

100-150 |

150-200 |

|

Power(KW) |

7.5+11.5 |

7.5+12.5 |

|

Weight(kg) |

4100 |

6480 |

|

Dimension(mm) |

5350*2000*3100 |

5200*2600*3550 |

Step Huller Beater

|

Model

|

Capacity(T/D)

|

Power(KW)

|

Weight(kg)

|

Dimension(mm)

|

|

GCLY50

|

180-200

|

17.5

|

4500

|

8300*2250*2950

|