We offer you 3-30 tons per hour of cassava starch milling grinder.

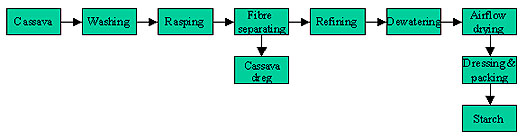

The processing technology is described briefly as follows: raw material washing, peeling off, general crushing, fine crushing, separation of residue and starch slurry, starch slurry refining, dewatering, airflow drying, dressing, and packing.

Flow chart

3-30 tons per hour of cassava starch processing equipments

|

|

| High efficient washer | Rasper | Vacuum sifter | Decorticator |

| Centrifugal sieve | Hydrocyclone | Automatic packer | Airflow dryer |

| High efficient cooling starch sifter | |||

Physical Chemistry Request Standard of Cassava Starch

| Moisture(%) | <=: Excellent grade: 14.0 First grade:15.0 Eligibility:15.0 |

| White degree(%) | (457nm blue ray)>=: Excellent grade:92.0 First grade: 88.0 Eligibility:84.0 |

| Fine degree(%) | (100mesh pass rate)>=: Excellent grade:99.8 First grade:99.5 Eligibility:99.0 |

| Speckle(pc/cm2) | =:Excellent grade:2.0 First grade:5.0 Eligibility:8.0 |

| Acidity(ml) | Excellent grade:14.0 First grade:18.0 Eligibility:20.0( Neutralization 100g dry starch consume 0.1mol/NaOH ) |

| Ash(%) | <=:Excellent grade:0.2 First grade:0.3 Eligibility:0.4 |

| Protein(%) | >=:Excellent grade:0.15 First grade:0.20 Eligibility:0.30 |

| Mucosity degree | >=:Excellent grade:1.30 First grade:1.30 Eligibility:1.30 |

| SO2 | <=:Excellent grade:0.001 First grade:---- Eligibility:---- |

| Quality Standard: | QB1840-93 |

Workshop View

|

|

|

|

Water gun

|

High efficient washer

|

Rasper

|

|

|

|

|

Centrifugal Sieve

|

Starch Hydrocyclone

|

Elevator

|

|

|

|

|

Airflow dryer

|

Starch Sifter

|

Automatic Packer

|

|

|

|

|

Hammer Crasher

|

Needle Mill

|

Blade Centrifuge

|