There are 2 kinds of hammer mills: small hammer mill used with small pellet mill; large hammer mill used with large pellet mill.

It is almost the most indispensable part for biomass pellet making.

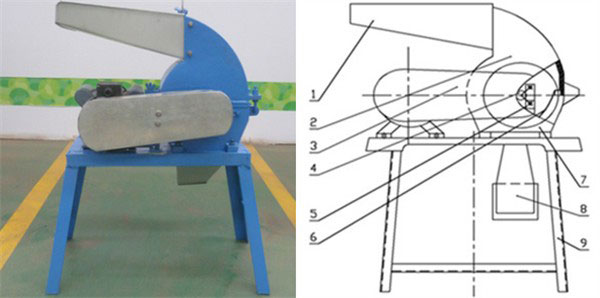

Small hammer mill

Small hammer mill is a basic part in small pellet plant.It can process corn, corn straw, peanut shell, bean straw, branches etc, materials with less than 14% moisture content.

Working Principle of Small Hammer Mill

When the materials go into the chamber of the hammer mill, they will be crushed by the high-speed of rotary hammers. The crushed materials are along the outer edge of the rotor under the function of centrifugal force and smashed by the squeezing, crashing, striking of the hammer, toothed plate and screen. The smashed materials are sent out of the hammer mill under the function of rotor and draught fan. The particles that don’t pass through the screen hole will be left in the hammer mill repeating the above steps until they are sent out of the hammer mill.

| Model | Power | Size(mm) | Net weight (kg) | Spindle Speed (r/min) | Screen | Capacity (kg/h) |

|---|---|---|---|---|---|---|

| 420B-7.5 | 7.5KW (electric motor) | 1200×1000×1220 | 285/310 | 3200 | 1.2-10 | 300-600 |

| 420B-11 | 11KW (electric motor) | 1200×1000×1220 | 310/330 | 3200 | 1.2-10 | 300-600 |

1. Feeding hopper, 2. Upper body, 3. Protective shell, 4. Rotor, 5. Blade, 6. Siever, 7.Lower body, 8. Discharging outlet, 9. Foundation frame.

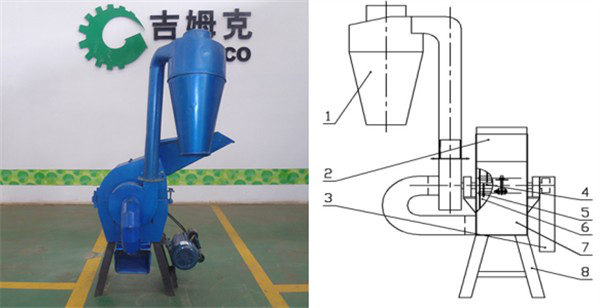

1. Cyclone, 2. Upper body, 3. Protective shell, 4. Rotor, 5. Blade, 6. Siever, 7.Lower body, 8. Foundation frame.

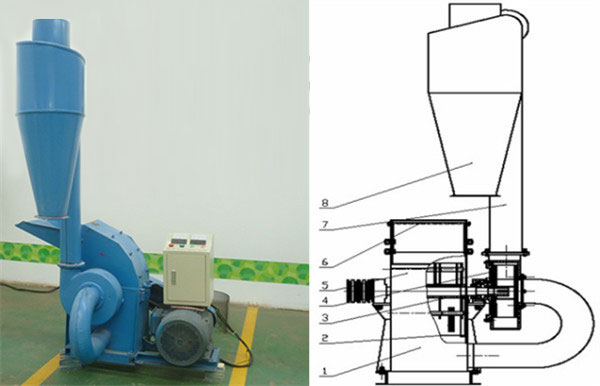

1. Lower body 2. Siever 3. Rotor 4. Air fan 5. Upper body 6. Feeding port 7. Discharging outlet 8. Cyclone

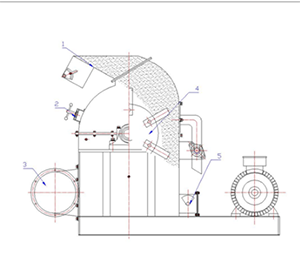

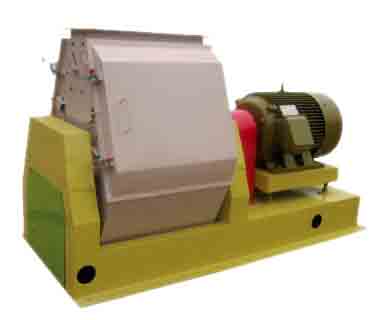

This kind of hammer mill can process crude fiber and large bulk materials, such as twigs, bark, plant roots, wood chips, garbage and chemical waste, etc.

Large Hammer Mill

In the complete pellet mill plant or complete briquette plant, hammer mill is an normal equipment because that there are few materials can be processed into pellets or briquettes directly. They usually need to be ground into proper size by the grinder that they can be processed into pellets or briquette machine.

1. Feeding hoper 2. Iron remove 3. Outlet 4. Rotor 5. Air additional open

Large hammer mill technical parameters

| Model | SFSPMX80×45 | SFSPMX80×60 | SFSPMX80×80 | SFSPMX80×100 | |

|---|---|---|---|---|---|

| Dia of Rotor(mm) | 800 | 800 | 800 | 800 | |

| Width of crushing room(mm) | 450 | 600 | 800 | 1000 | |

| RPM of Main Shaft(rpm) | 2400 | 2400 | 2400 | 2400 | |

| Linear speed of Hammer(m/s) | 100 | 100 | 100 | 100 | |

| Number of hammers | 36 | 48 | 72 | 96 | |

| Main motor(kw) | 18.5/22 | 30/45 | 45/75 | 75/90/110 | |

| Bearing model | NSK2216 | NSK 2216 | NSK 2317 | NSK 2317 | |

| Belt model | C2692*5 | C2692*5 | C2692*5 | C2692*5 | |

| Damping rubber | 6 | 6 | 6 | 6 | |

| Sieve size | 445*1250 | 595*1250 | 795*1250 | 995*1250 | |

| Over size | length(mm) | 2105 | 2105 | 2105 | 2305 |

| width(mm) | 980 | 1172 | 1372 | 1520 | |

| height(mm) | 1600 | 1600 | 1600 | 1600 | |

| Sucking volume m3/min | 74 | 91 | 110 | 141 | |

SFSW Series Sieve-free Hammermills

The SFSW Series Sieve-free Hammermills combined with air separator or grading sieve can enhance the efficiency of crushing greatly. The SFSW Series Sieve-free Hammermills use 360° metal scaleboard, free of sieve. Even if there are impurities such as iron nails, bolts, the machine won't be damaged.

Our hammermill is very suitable to pulverize the material that easily blocks the sieve or very fine material.

Our hammermill save money and energy consumption.

| Model | SFSPZ70*75 | SFSPZ112*75 | SFSPZ130*75 | 999I | 999II | 999III | 998I | 998II | 998III |

| Powder(KW) | 75/90 | 110/132 | 160/200 | 75/90 | 110/132 | 160/200 | 18.5/22 | 30/37 | 55 |

| Capacity(t/h) | 5.5-6.5 | 8-10 | 11-15 | 12~15 | 25~35 | 38~50 | 1~4 | 5~6 | 6~10 |

|

|

|

SFSPZ Series Hammermill

|

999I,II,III Series Hammermill

|

|

|

|

998I,II,III Series Hammermill

|

SFSW Series Hammermill

|

Features of Hammermill:

- - are able to produce a wide range of particle sizes.

- - work with any friable material and fibre.

- - ease of use.

- - lower initial investment when compared with a roller mill.

- - minimal maintenance needed.

- - particles produced using a hammermill will generally be spherical, with a surface that appears polished.

Anyang General International Co.,Ltd is a main manufacturer and supplier of Hammermills from China. We offer you all kinds of Feed Hammermill and Wood Hammermills.