Briquetting is a process during which biomass is compressed under high pressure and high temperature.

The self bonding of biomass to form a briquette involves the thermo-plastic flow of the biomass. The lignin content that forms naturally in biomass is liberated under high pressure and temperature. Lignin serves as the glue in the briquetting process, thus no artificial binder need to be used. So the ouput briquette is a type of clean and green fuel that is ideal for use in furnaces, boilers and open fires. The density of the briquettes is 1100~1300kg/m.

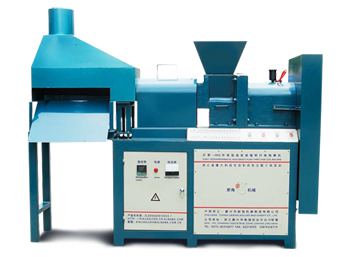

GCBC Series Biomass Briquetting Press

|

|

| GCBC- I | GCBC-II |

| Model | GCBC- I | GCBC-II |

|---|---|---|

| Output capacity kg/h | 180-210 | 300-350 |

| Motor Power (kw) | 15 | 18.5kw |

| Electric heater (kw) | 2.2kw*2 | 2.2kw×2 |

| Life of the inner former | 1-2years | 1-2years |

| Size of briquettes | Dia.50mm*L.480mm | Dia.60mm*L.500mm |

| Size of inside hole | Dia.16mm | Dia.16mm |

| Density of briquettes | 1.3 g/cm3 | 1.3 g/cm3 |

| Weight(kg) | 700kg | 1000kg |

| Overall dimension(mm) | 2700*600*1600 mm | 2000*600*1700 mm |

The shape of the biomass briquettes or charcoal briquettes can be customized by changing different forming parts. Feel free to tell us your specific needs if you want to make wood briquettes in other shapes.

Our Briquetting Press is in screw type, it produces cylindrical briquettes with a hole through the centre of the cylinder. The briquettes produced by a screw press is easily handled and stacked, and they have some advantages over those produced using the ram and die press. While the briquettes produced by a piston press are completely solid, screw press briquettes on the other hand have a concentric hole which gives better combustion characteristics due to a larger specific area. The screw press briquettes are also homogeneous and do not disintegrate easily. Having a high combustion rate, these can substitute for coal in most applications and in boilers.

Features of GCBC Series Biomass Briquetting Press:

- 1. Heating section - we adopted two heat collars which are made from thick copper wires and are ceramic inside.

- 2. An attractive feature on the forming hopper is that we added a movable plate on the bottom. It has two functions, one is you can clean it easily. The other is that you can discharge the inputted material when it is jammed.

- 3. Lubricating System - The gear box is equipped with lubricating system. Moreover, to oil the gear box properly, our briquette machine is designed with an exhaust function which can help maintain consistent air pressure.

- 4. Auto Cutting System - It’s a simple piece of equipment composed of two steel plates. (Please see the picture), and briquettes can be automatically cut in uniformed lengths.

|

|

|

| 1. Heating section | 3. Lubricating System | 4. Auto Cutting System |

GCBA Series Biomass Briquetting Press

|

|

|

Briquetting Press Model GCBA I (11kw motor)

|

Briquetting Press Model GCBA II (15kw motor)

|

|

|

|

Briquetting Press Model GCBA III (18.5kw motor)

|

Wood Briquettes made from Briquetting Press

|

| Model | GCBAI | GCBAII | GCBAIII |

|---|---|---|---|

| Output kg/h | 80-120 | 120-150 | 180-230 |

| Motor Power (kw) | 11kw(energy saving type with gear box) | 15kw(without gear box) | 18.5kw |

| Electric heater (kw) | 1.5kw*3pcs | 1.5kw*3pcs | 2kw*3pcs |

| Weight(kg) | 650kg | 650kg | 900kg |

| Overall dimension(mm) | 1780*750*1290 | 1650*600*1260 | 1860*800*1360mm |

| Size of finished products |

Diameter: 30,40, 50mm |

Diameter: 30,40,50mm |

Diameter: 60,70,80,90,100mm |