Certainly we could classify raw materials into relevant types according to the practical fields the pellet products are finally used. While considering the decisive role the materials play in the pelletizing process, here we will try to sort them based on the difficulty in their shape-forming process.

First, cereal plants containing rich starch like barley, wheat, corn and surname can be more easily compressed into pellets products due to the strong stickiness of starch. Second, materials like beans, soybeans, aquatic products of fish, shrimp, and organic refuse like paper pulp are high in protein and enjoy high plastic performance. Next are the ones with relatively high content of fat. This includes the seed of sunflower, sesame, peanuts, coconut and soon. A proper quantity of fat may contribute to the forming of pellets, whereas, excessive fat will lower the quality of pellets. Then comes the raw material with high content of coarse fiber like leaves, roots, branches of trees, stalks of crops and shells of seeds, saw dust and wood chips. As a traditional agricultural country, this kind of material is popular in China and has a large quantity in store. On the other hand, because of the high content of fiber, these materials are not easy to squeeze and form particles with solid shapes. And another big difference of this kind from the above types is that it can make the most use of abandoned wood and agricultural residues. Besides materials of this kind are mostly made into biomass fuels both for family and industry use, while other types are most used to produce animal feeds. Also, there are other recyclable wastes from our daily life and livestock farm, and organic waste water, such as food residues, waterway sledges construction scraps and animal feces. This sort of materials is also mostly used to be made into fuels.

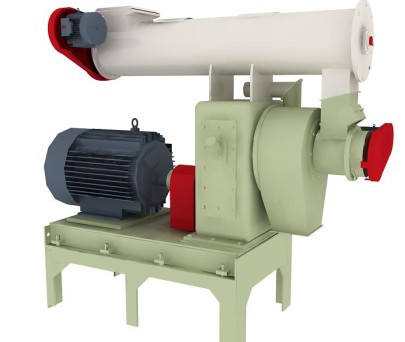

See more about our pellet mill